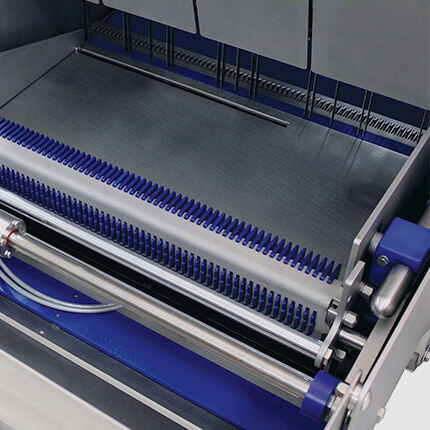

FLS Series

Semi-automatic slicer, completely washable also internally.

Extremely versatile solution for the processing of fresh meat, thanks to the external electrical system that makes it easier to access the components for cleaning.

- Easy sanitation without any tools

Get perfect, thorough sanitation with no tools needed for either the cleaning operations and blades replacement

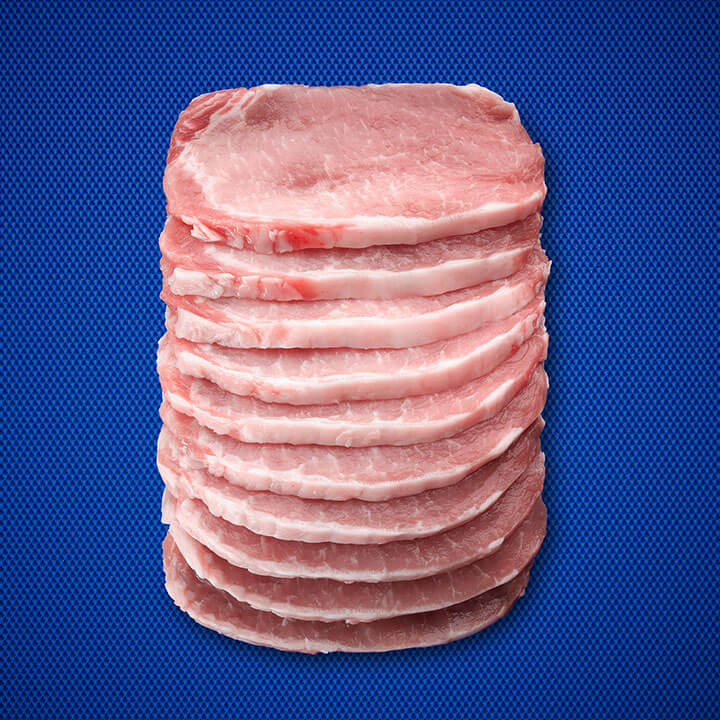

- Extremely adaptable for maximum performance

With a wide range of cutting options, FSL’s cutting parameters can be adjusted to allow for the maximum quantity of product to be sliced.

- Field proven productivity

FSL has proven to deliver a cutting capacity of up to 2.000 Kg/h depending on the product conditions.

Technical Specifications

- Through-pusher Option:

FSL can be equipped with personalized through-pushers designed to match the product’s shape and infeed position, in order to obtain an end-result of neat slices grouped according to the original appearance of the product.

- BI Option:

BI version available for bone-in products, with sectioned pressing system.

Technical Data

| Height (FSL600/FSLYC/FSL1000): | 1480 mm - 58.27" / 1436 mm - 56.55" / 1494 mm - 58.84" |

| Width (FSL600/FSLYC/FSL1000): | 1694 mm - 66.69" / 1979 mm - 77.91" / 2093 mm / 82.40" |

| Depth (FSL600/FSLYC/FSL1000): | 1564 mm - 61.56" / 1793.3 mm - 68.48" / 1583 mm - 62.3" |

| Weight (FSL600/FSLYC/FSL1000): | 800 Kg - 1102 lb / 800 Kg - 1102 lb / 1270 Kg - 2800 lb |

| Motor power: | 4.2 / 5.5 Kw |

| Noise level: | 68 db |

| Operator control circuit: | 24 V |

| Maximum working width(FSL600/FSLYC/FSL1000): | 586 mm - 23.07" / 610 mm - 24.01" / 1000 mm - 39.40" |

| Minimum slicing pitch boneless: | 2.5 mm - 0.09"/ 5 mm - 0.19" |

| Air consumption : | 30 lt/min |

Please contact us for further information and questions.