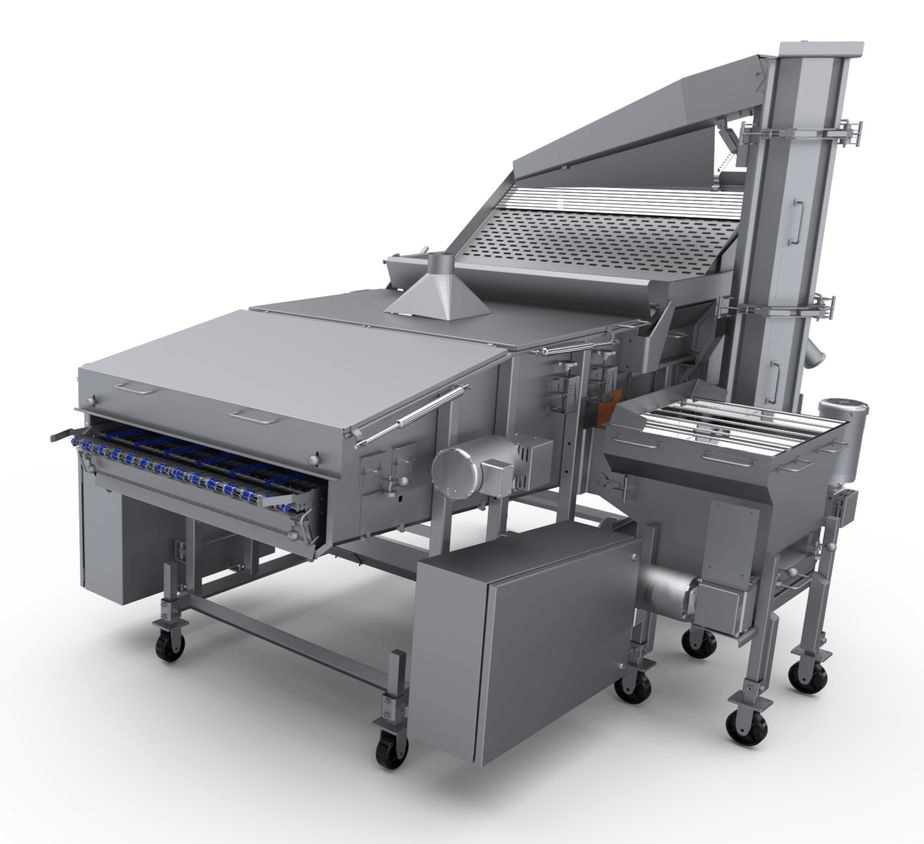

MP116 J-CRUMB BREADER

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry’s standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book.

It has survived not only five centuries, but also the leap into electronic typesetting, remaining essentially unchanged. It was popularised in the 1960s with the release of Letraset sheets containing Lorem Ipsum passages, and more recently with desktop publishing software like Aldus PageMaker including versions of Lorem Ipsum.

Construction is all stainless steel with US Standard bearings, belting and shafts. Direct feed 9” vertical screw with bottom direct drive. 3/8” .082 wire belting or 1/2” pitch to optimize product handling

Flour coating configuration for free flow and Japanese crumb coatings

Excess breading removal set up with two blow-off tubes above product zone for tie into plant central blower system

MP rotating top flow breading distribution system

Technical Specifications

Standard casters with stainless steel frame and Phenolic Wheels

Rotating belt vibrator

150 lb. breading capacity feeder with variable speed hydraulic drive allows consistent addition of breading blending new breading with return for even application to product

Positive cam/lock on all access doors

Lift cylinder on discharge chute, hopper and covers

Adjustment/support for discharge of batter applicator

Belt tension adjustment for hopper/main belt

Stand-off bearings for maximum sanitary design

Engineered for safety, user friendliness and optimum uptime

Operator controls ergonomically designed

40” usable belt width

Please contact us for further information and questions.